Lumengy Paver Light Manufacturing Process

Introduction:

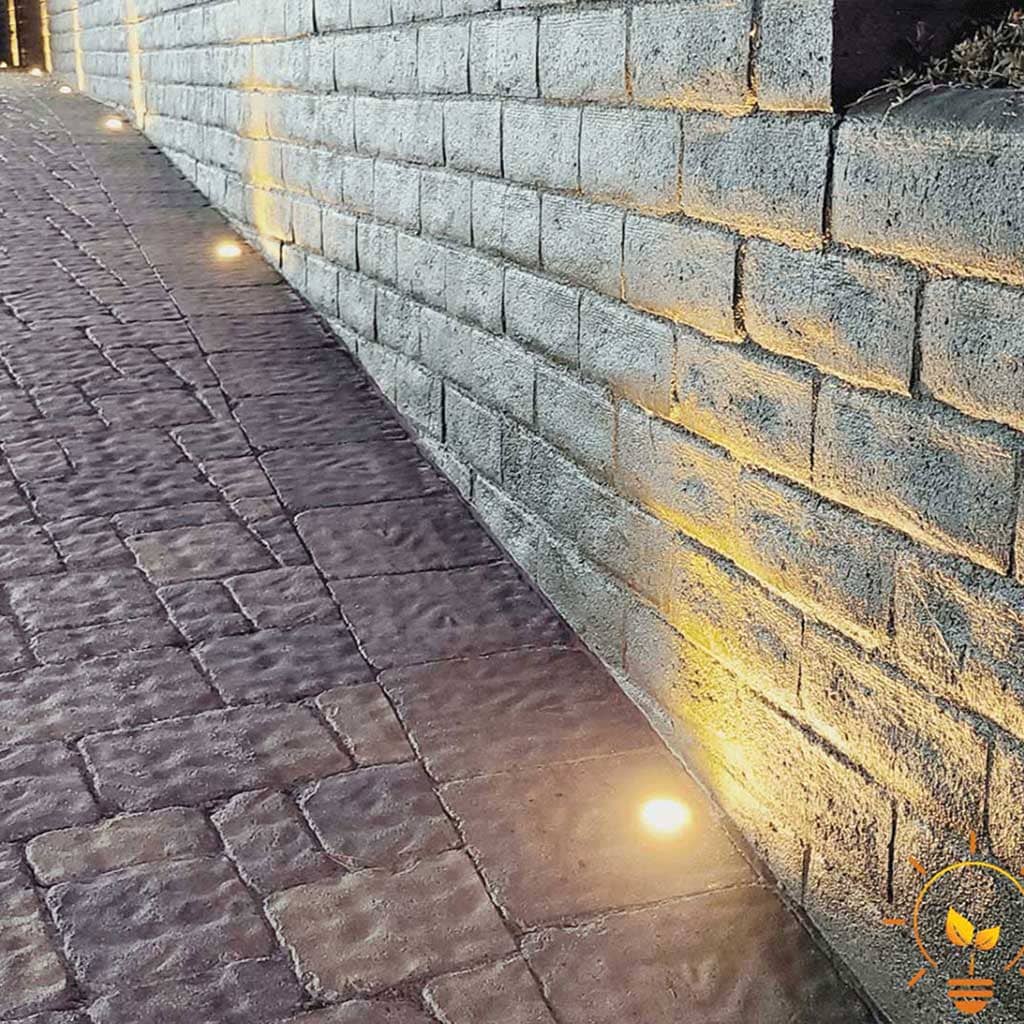

Welcome to the Lumengy family, where our journey began as paver contractors in Southern California. With firsthand experience in the challenges of paver installations, we've evolved into manufacturers of innovative paver lights, perfectly tailored to enhance outdoor spaces.

Materials:

At Lumengy, we believe in using only the finest ingredients. Our paver lights feature top-quality LEDs with an impressive lifespan of 50,000 hours, high-grade stainless steel, and premium glass that is free from iron for optimal light transmission. Every component is meticulously chosen for durability and performance.

Manufacturing:

Our manufacturing process starts with state-of-the-art machines custom-built to our specifications. This enables us to achieve fast and precise assembly of our paver lights. Lumengy has developed a unique assembly line that ensures top-quality installations and long-lasting products.

Quality Control:

Quality is paramount at Lumengy. Each product undergoes rigorous testing for waterproofing in both cold and hot water, EMF radio interference, and accurate voltage, watts, and lumens. We subject every light to 72 hours of testing in extreme temperature conditions to simulate the harshest environments before it's packed and shipped.

Constant Development of New Ideas:

Constant Development of New Ideas:

We maintain close relationships with paver factories and contractors, continuously listening to their needs and innovating new lighting solutions for challenging projects. Our commitment to staying ahead of the curve ensures that we always deliver cutting-edge products.

Summary:

Lumengy paver lights are patented designs, crafted to be unique, robust, and visually stunning. With multiple top-quality LEDs and high-quality materials, they offer unparalleled lighting effects. We invite you to experience the Lumengy difference for yourself. Contact us with any questions or to place an order today.